What is my group chemical device?

- Half-boiled egg cooker prototype.

- Is to assist coffee shop workers with their job.

- Perfectly cooked half-boiled eggs by using our device without any human error.

How does it work?

- When the temperature of the water is at the right temperature.

- The egg will be submerged into the pot of hot water.

- The timer will start when the egg is submerged.

- The egg will be lifted up after a specific time.

- Therefore, the consistent perfectly cooked half-boiled egg is achieved.

How my team planned, allocated the tasks, and executed the project

Step 1: We used the design thinking process. Eg: Ideations of the product, TRIZ and Part -whole analysis.

Step 2: We formed the BOM (BILL OF MATERIALS).

Step 3: We formed the Gantt chart.

Step 4: Allocation of the task.

Task | Name |

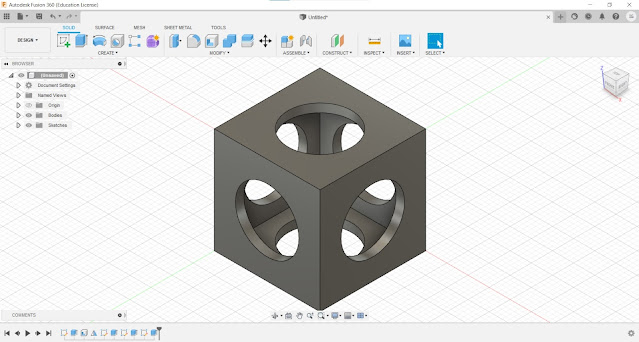

CAD modelling of frame, box, attachments Frame construction Gather materials, components | Alex |

3D printing of attachments DC motor coding | Emily |

Temperature sensor coding Test run for combined code | Iman |

Laser-cutting of box | Syufyan |

Product assembly | Everyone |

We added 2 powerbank to power the Arduino Maker Uno and H-bridge for portability. Furthermore, we add an on/off switch so that it is easy to turn on/off with the box.

- The basket was not in the right starting position

- The code only runs when the temperature is at the set point.

- The DC motor does not have the braking power needed to hold the basket in place (gravity)

- The rest of the code runs when the temperature has been reached.

- Use a bit of power to hold the motor to hold it in place.

- Using the absent braking power - let gravity pull the basket down.